Precision Components for E-Mobility and Electric Vehicles

The rapid growth of e-mobility—particularly the emergence of electric vehicles—is profoundly transforming the automotive and urban mobility industries. Electric and hybrid vehicles, as well as charging solutions, require mechanical and electrical components of absolute reliability.

Since 2010, AMD Décolletage has experienced strong growth by developing its expertise in precision turning for the automotive industry. We specialize in electric vehicles (EVs) and electrification, offering high-performance high-power charging interconnection solutions (connectors/disconnectors).

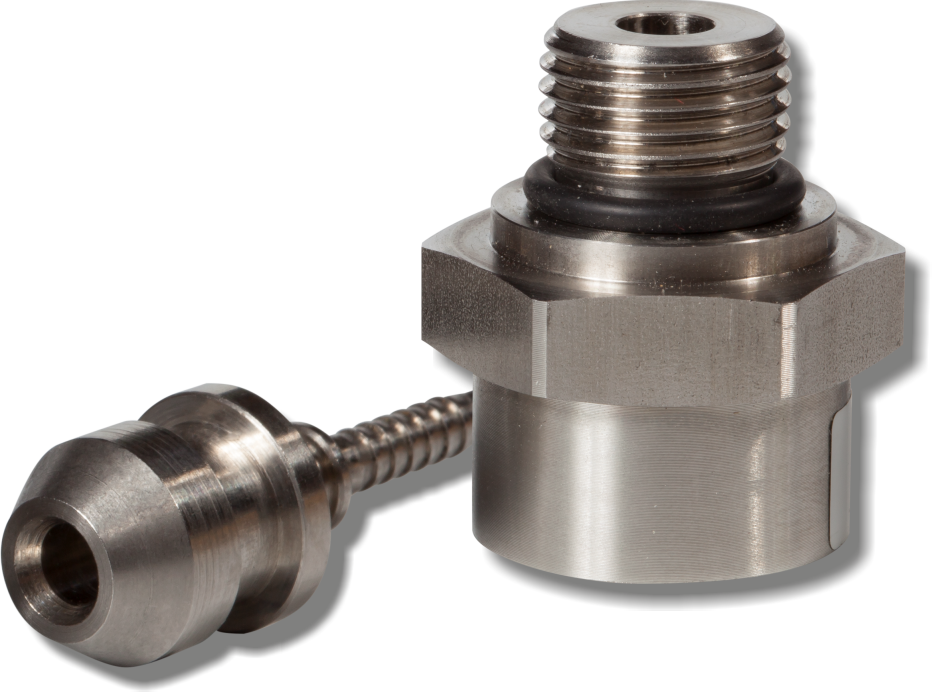

AMD Décolletage has become a trusted partner of leading Tier-1 suppliers and renowned companies operating in the connectivity, electromobility, and automotive markets. We specialize in the manufacturing of power and high-power contacts integrated into charging plugs (Type 1 and Type 2, CCS 1 and 2, NACS, MCS, GBT, and ChaoJi) for battery networks.

Today, AMD continues to strengthen its capabilities in these sectors and pursue its development, leveraging its know-how in high value-added applications and innovative markets.

Our Expertise Serving E-Mobility

AMD Décolletage designs and manufactures electrical contacts, connector parts, and mechanical components for:

- Electric and hybrid vehicles (EV/HEV): battery interfaces, power systems, high-voltage connectors

- Charging infrastructures: fast-charging stations, high-current connectivity systems

- Energy management systems: machined components for converters, inverters, and cooling modules

Challenges in the E-Mobility Sector

Driven by the rapid expansion of electric mobility and fast-evolving technologies, the e-mobility sector is undergoing major transformations. Industrial players must address significant technological, environmental, and industrial challenges to meet increasing demands for performance, reliability, and sustainability.

Energy Transition and Electrical Performance

- Supporting the development of cleaner, more energy-efficient mobility solutions

- Ensuring the reliability of components used in battery, power, and energy management systems

- Optimizing electrical performance while meeting safety and lifetime requirements

Technological Innovation and Industrial Requirements

- Addressing challenges related to miniaturization, high voltage, and component precision

- Integrating continuously evolving technologies linked to embedded electronics and intelligent systems

- Adapting industrial processes to ensure quality, repeatability, and large-scale competitiveness

Sustainability, Supply Chain, and Environmental Responsibility

- Securing the supply of raw materials and critical components

- Reducing the environmental footprint of products and manufacturing processes

- Integrating recyclability and sustainability considerations from the design stage

Tailored Support

Our team supports you throughout the entire production process, from feasibility studies to manufacturing in small, medium, or large series.

Discover our “From Design to Manufacturing” offering.

Technical Advantages of AMD Décolletage

Certified Quality and Traceability

Our industrial processes comply with the most stringent standards:

- ISO 9001 – Quality management

- IATF 16949 – Automotive-specific requirements

- ISO 14001 – Environmental commitment and sustainability

Production Flexibility

We manufacture small, medium, and large series with the same level of precision, ensuring:

- Optimized lead times

- Enhanced competitiveness

- Adaptability to evolving market needs

Innovation and Performance

Each year, AMD invests 10% of its revenue in innovation:

- Machining of new conductive and lightweight materials

- Digitalization and traceability (Industry 4.0)

- Material optimization to reduce waste and carbon footprint

E-Mobility Applications

AMD Décolletage manufactures precision components for:

- Electric and hybrid automotive: high-power connectivity parts, safety components, battery interfaces

- Smart urban mobility: electric scooters, bicycles, and micro-mobility solutions

- Charging stations and infrastructures: connector components, safety systems, and high-strength mechanical parts

- Industry 4.0 applied to mobility: components integrated into connected and intelligent systems

Why Choose AMD Décolletage for Your E-Mobility Projects?

![]() Recognized expertise in high-precision machining

Recognized expertise in high-precision machining

![]() Quality and environmental certifications tailored to the automotive and e-mobility sectors

Quality and environmental certifications tailored to the automotive and e-mobility sectors

![]() Flexible, international production capacity (85% export)

Flexible, international production capacity (85% export)

![]() Innovation partner supporting the transition toward sustainable, low-carbon mobility

Innovation partner supporting the transition toward sustainable, low-carbon mobility