Our Turning and Machining Technologies

At AMD Décolletage, our fleet of 200 machines includes single-spindle and multi-spindle machines, cam-operated or CNC, rotary transfer machines with 6, 8, 12 and 20 stations, as well as Escomatic-type machines.

Our entire machine park is managed through a LEAN 4.0 digital control system, with machines connected to our servers for real-time monitoring of all production (EMS–ERP, Industry 4.0). Our production management software (Cimag Production) secures monitoring and full traceability while continuously optimizing the industrial performance of our machine park.

Machine Types

![]() Single-spindle machines

Single-spindle machines

![]() Multi-spindle machines

Multi-spindle machines

![]() Rotary transfer machines (6, 8, 12 and 20 stations)

Rotary transfer machines (6, 8, 12 and 20 stations)

![]() Escomatic-type machines

Escomatic-type machines

Comparison of the Four Technologies in Our Machine Par

![]() Single-spindle → Flexibility, small and medium series, high precision

Single-spindle → Flexibility, small and medium series, high precision

![]() Multi-spindle → Large and very large series, simple parts, high speed

Multi-spindle → Large and very large series, simple parts, high speed

![]() Rotary transfer → Large series, complex multi-operation parts

Rotary transfer → Large series, complex multi-operation parts

![]() Escomatic → Ultra-high output for standardized micro-parts

Escomatic → Ultra-high output for standardized micro-parts

Single-Spindle Machining: Certified High Precision

Our expertise in single-spindle machining enables us to produce complex, technical and miniaturized parts with uncompromising precision. Our latest-generation single-spindle machines ensure flexible and competitive production for small, medium and large series alike.

Single-Spindle Machining: Flexibility and Performance

Single-spindle screw machining is an ideal solution for:

![]() Production of individual parts and small high value-added series

Production of individual parts and small high value-added series

![]() Machining complex geometries with high repeatability

Machining complex geometries with high repeatability

![]() Manufacturing prototypes or industrial pre-series

Manufacturing prototypes or industrial pre-series

Principle of Single-Spindle Technology

A single spindle (chuck) operates at a time. Each part is machined sequentially.

Characteristics

-

Simpler and less costly machine

-

Ideal for small and medium series, prototypes or complex parts requiring multiple operations

-

Longer cycle times, as each part is produced individually

Advantages

-

High flexibility when changing production

-

Well suited for precision parts and small to medium quantities

Limitations

-

Limited productivity

-

Less cost-effective for large series

High-Precision Multi-Spindle Machining – Flexible Series for Industry

Thanks to a fleet of latest-generation multi-spindle machines, we ensure flexible and competitive production for small, medium and large series. We support global OEMs across numerous industries.

Multi-Spindle Technology Serving Performance

Multi-spindle screw machining allows several machining operations to be performed simultaneously on the same part, providing:

![]() Increased productivity through reduced cycle times

Increased productivity through reduced cycle times

![]() Dimensional precision meeting the tightest tolerances

Dimensional precision meeting the tightest tolerances

![]() Perfect repeatability, even at high volumes

Perfect repeatability, even at high volumes

![]() Cost optimization while ensuring consistent quality

Cost optimization while ensuring consistent quality

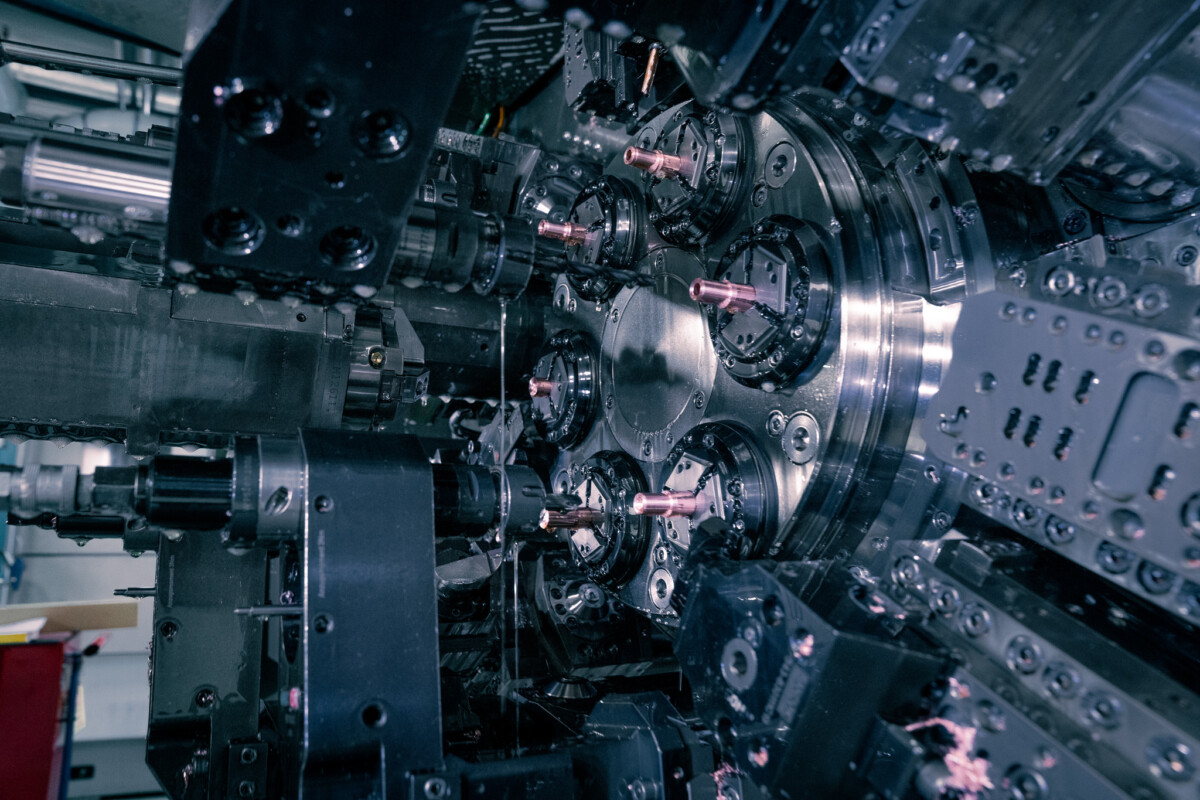

Principle of Multi-Spindle Technology

Several spindles (typically 6 or 8) operate in parallel. Each spindle performs a different operation on a part, and the parts move from one station to the next.

Characteristics

-

More complex and costly machine

-

Designed for large series and high-speed production

-

Very short cycle times, as multiple parts are machined simultaneously

Advantages

-

Very high productivity

-

Highly cost-effective for large volumes

Limitations

-

Less flexible (long setup times when changing references)

-

High initial investment

Rotary Transfer Machine Technology (6, 8, 12 and 20 Stations)

Operating Principle of a Rotary Transfer Machine

A rotary transfer machine is designed to produce complex parts in large series. The part is fixed on a rotating table that moves from one station to another. Each station performs a specific operation (drilling, milling, tapping, turning, etc.). At the end of the cycle, the part is fully machined.

Characteristics

-

Number of stations: typically 6 to 24, depending on complexity

-

Production: very fast, with several operations performed in parallel

-

Flexibility: lower than single-spindle, but more adaptable than multi-spindle for complex parts

-

Investment: very high, but offset by productivity

Advantages

-

Short cycle time: all operations integrated into a single machine

-

High precision, as the part remains fixed on the same fixture

-

Ideal for complex parts in large series

Limitations

-

Long setup times when changing references

-

Higher cost

-

Less suitable for small series

Escomatic-Type Machines

Principle of the Technology

Escomatic machines are screw machines without a rotating chuck:

-

The bar does not rotate; the cutting tool performs the cutting motion

-

The bar is continuously fed through the machining zone

-

This technology is specialized for the production of small cylindrical parts in very large series

ESCOMATIC = ultra-high productivity for small cylindrical parts in large series, using a unique system where the bar remains stationary and the tool rotates.

Characteristics

-

Extremely high output: up to several thousand parts per hour

-

Bar diameter: typically from 0.3 mm to 6 mm

-

Possible operations: turning, threading, grooving, drilling, etc.

-

Compact: small footprint, ideal for mass production

Advantages

-

Extreme productivity for small parts

-

Very low unit cost for large series

-

Reduced vibration (fixed bar), ensuring good precision

-

Rapid bar change thanks to continuous feeding

Limitations

-

Limited to small parts (small diameters)

-

Less suitable for complex parts

-

Specific investment (dedicated machines)

Application Examples

-

Electronics / Connectivity: contacts, pins

-

Watchmaking: shafts, miniature screws

-

Automotive: small precision parts (pins, shafts)

-

Medical instrumentation: micro-components

Technical Advantages of Machining at AMD

![]() Extreme precision for tight tolerances

Extreme precision for tight tolerances

![]() Flexibility: production adapted to small, medium and large series

Flexibility: production adapted to small, medium and large series

![]() Certified quality: ISO 9001, IATF 16949 (automotive) and ISO 14001 (environment)

Certified quality: ISO 9001, IATF 16949 (automotive) and ISO 14001 (environment)

![]() Innovation & Industry 4.0: real-time monitoring, automation, energy efficiency

Innovation & Industry 4.0: real-time monitoring, automation, energy efficiency

![]() Environmental commitment: optimized processes to reduce carbon footprint

Environmental commitment: optimized processes to reduce carbon footprint

Industry Applications

AMD single-spindle screw machining serves advanced industries requiring rigor and reliability:

-

Automotive & e-mobility: electrical contacts, powertrain components, safety systems

-

Connectivity: mini-connectors, high-precision contacts

-

Industry 4.0 & data centers: precision components for smart equipment

Why Choose Us?

By choosing AMD Décolletage for your single-spindle machining projects, you benefit from:

![]() Over 45 years of experience in precision machining

Over 45 years of experience in precision machining

![]() Recognized multi-sector expertise with an international footprint (85% export)

Recognized multi-sector expertise with an international footprint (85% export)

![]() Full control of quality and traceability

Full control of quality and traceability

![]() A premium strategic partner capable of supporting your projects from design to serial production

A premium strategic partner capable of supporting your projects from design to serial production