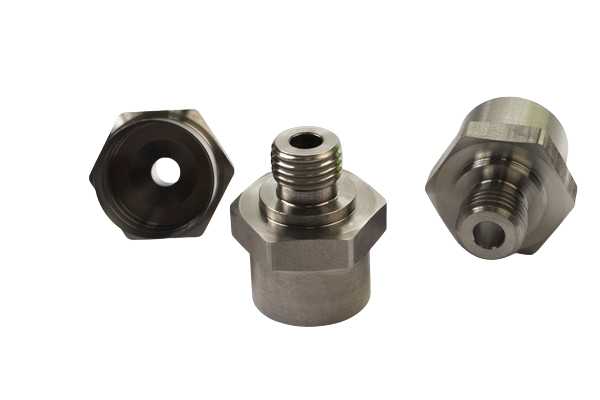

Precision Turning for the Automotive Industry – IATF 16949 Certified Parts

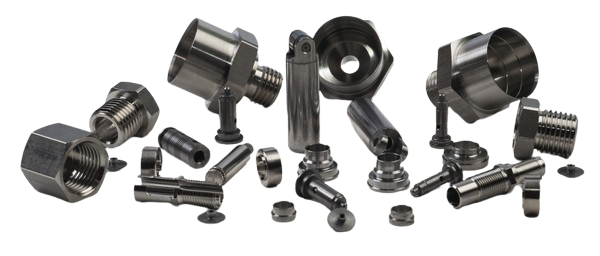

With over 20 years of experience in the automotive industry, AMD Décolletage supports Original Equipment Manufacturers (OEMs) and automotive manufacturers in the production of high-precision mechanical parts for assemblies and sub-assemblies used in functional and safety-critical applications for passenger vehicles, commercial vehicles, trucks, and buses.

At AMD Décolletage, our customers find the know-how and expertise required to meet their technical, industrial, and economic requirements. We manufacture and deliver more than 350 million parts per year to automotive customers worldwide.

Trusted by Leading Tier-1 Suppliers and System Manufacturers

Major equipment suppliers and manufacturers of functions and sub-functions rely on us for the supply of machined mechanical components used in key applications for automotive and electric vehicle manufacturers, including:

|

|

State-of-the-Art Automotive Technology

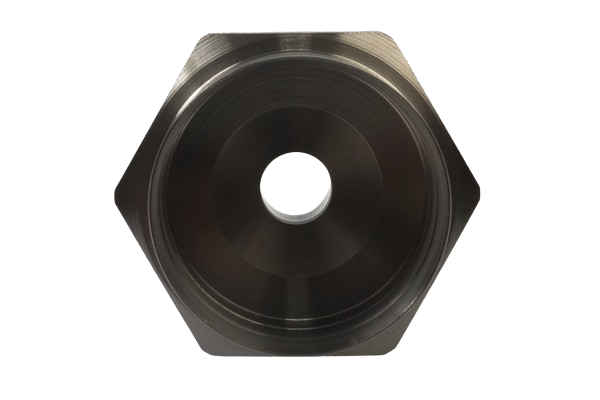

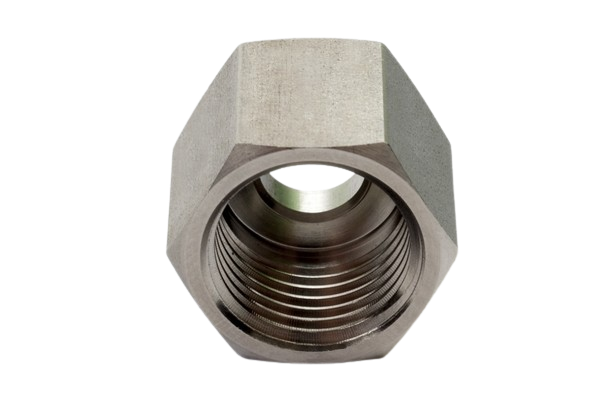

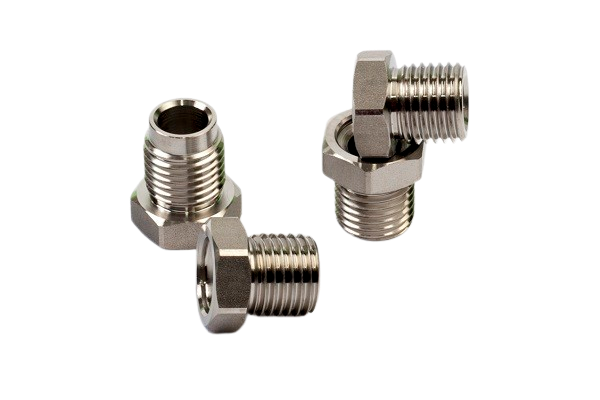

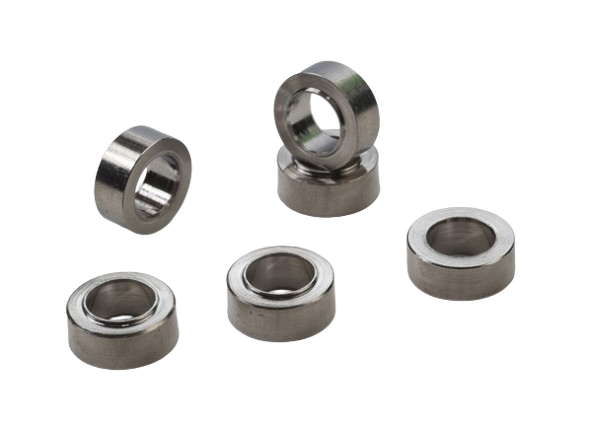

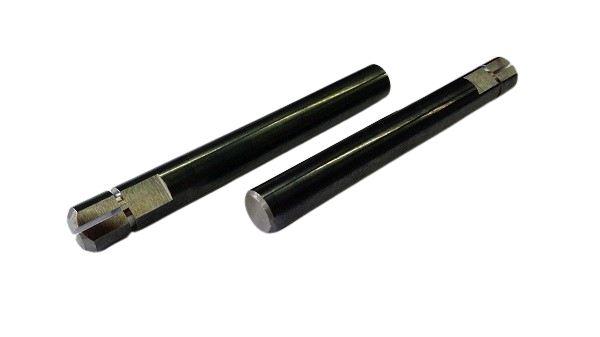

High-Precision CNC Turning

AMD Décolletage masters the full range of CNC turning and precision machining technologies, suitable for small, medium, and large production runs.

We machine a wide range of materials:

- Special steels and stainless steels

- Lightweight alloys for vehicle weight reduction

- Non-ferrous metals (brass, aluminum, copper)

- Materials adapted to new electric and hybrid mobility solutions

Challenges in the Automotive Sector

The automotive industry is undergoing a major transformation driven by the energy transition, technological advancements, and the globalization of value chains. Automakers and suppliers must now face significant challenges to remain competitive, comply with regulations, and meet increasingly demanding market expectations.

Building on this experience, since 2010 we have been supporting the sector’s ecological transition and vehicle electrification. The shift toward e-mobility requires expertise in the manufacturing of connectors and contacts, as well as high-precision engineering to address electrification challenges such as power supply, high current, lightweight design, fast charging, cooling, and cabling.

Energy Transition and Environmental Standards

- Reducing vehicle CO₂ emissions and adapting to increasingly stringent environmental regulations

- Integrating alternative powertrains (electric, hybrid, hydrogen) while ensuring performance and affordability

- Developing more sustainable manufacturing solutions and materials across the entire vehicle life cycle

Technological Innovation and Industrial Competitiveness

- Mastering advanced technologies, from connected vehicles to autonomous driving, to meet market and consumer expectations

- Integrating electronics, embedded software, and cybersecurity into increasingly complex architectures

- Investing in R&D to remain competitive amid new market entrants and rapidly evolving use cases

Supply Chains, Resilience, and Workforce

- Addressing supply chain volatility, particularly for semiconductors and critical materials

- Strengthening industrial resilience to limit the impact of global disruptions (pandemics, geopolitical tensions)

- Attracting and training skilled talent to meet the sector’s technical and digital needs

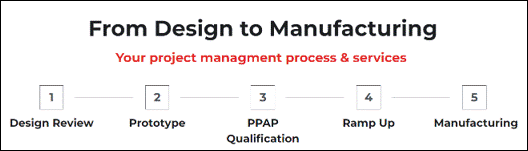

Tailored Support

Our team supports you throughout the entire production process, from feasibility studies to manufacturing in small, medium, or large series.

Discover our “From Design to Manufacturing” offering.

Quality Control and Traceability

Each part benefits from rigorous monitoring through automated dimensional and visual inspections. Full production traceability meets the requirements of global automotive suppliers.

Technical Advantages for Your Automotive Projects

![]() IATF 16949 certification: compliance with international automotive quality standards

IATF 16949 certification: compliance with international automotive quality standards

![]() Industrial flexibility: from prototyping to high-volume production

Industrial flexibility: from prototyping to high-volume production

![]() Innovation and e-mobility: solutions tailored to electric and hybrid vehicles

Innovation and e-mobility: solutions tailored to electric and hybrid vehicles

![]() Reliability and safety: critical parts for engines, transmissions, safety systems, and connectivity

Reliability and safety: critical parts for engines, transmissions, safety systems, and connectivity

![]() Environmental commitment: responsible production certified to ISO 14001

Environmental commitment: responsible production certified to ISO 14001

Applications in the Automotive Industry

Our solutions address the needs of key automotive sectors:

- Powertrain: precision parts for internal combustion and electric motors

- Transmissions & chassis: robust and lightweight components

- Safety systems: parts for airbags, ABS, and braking systems

- E-mobility: components for batteries, high-voltage connectors, and sensors

- Smart vehicles (Industry 4.0): solutions for automotive sensors and connectivity

Why Choose AMD Décolletage for Your Automotive Projects?

By choosing AMD Décolletage, you benefit from a premium strategic partner recognized for:

![]() High-level technical expertise in precision turning

High-level technical expertise in precision turning

![]() International certifications ensuring quality and reliability

International certifications ensuring quality and reliability

![]() The ability to adapt to the evolving automotive industry

The ability to adapt to the evolving automotive industry

![]() A sustainable approach integrated into every stage of production

A sustainable approach integrated into every stage of production

We are not just a subcontractor — we are a trusted partner, driving innovation and meeting the challenges of tomorrow’s mobility.

Move toward the mobility of tomorrow with AMD Décolletage