Precision Turning for Connectivity

For over 40 years, AMD Décolletage has been designing and manufacturing high-precision contacts and components for major companies in the connectivity sector.

In an increasingly digital world, connectors are everywhere:

- Aerospace: avionics systems, sensors, flight controls

- Automotive: wiring harnesses, ADAS or LIDAR systems, power buses, batteries, charging connections

- Telecommunications: fiber optic networks, antennas, routers

- Consumer or Industrial Electronics: smartphones, computers, peripherals, robots, automation systems

- Industry: automation, robots, IoT sensors, power supplies

- Energy: wind turbines, solar panels, storage systems

- Defense: military equipment, embedded systems

- Medical: imaging devices, implantable devices

- Railway: signaling systems, electric traction

- Space: satellites, launch vehicles, communication systems

A Connector: An Essential Electromechanical Component for Information Transmission

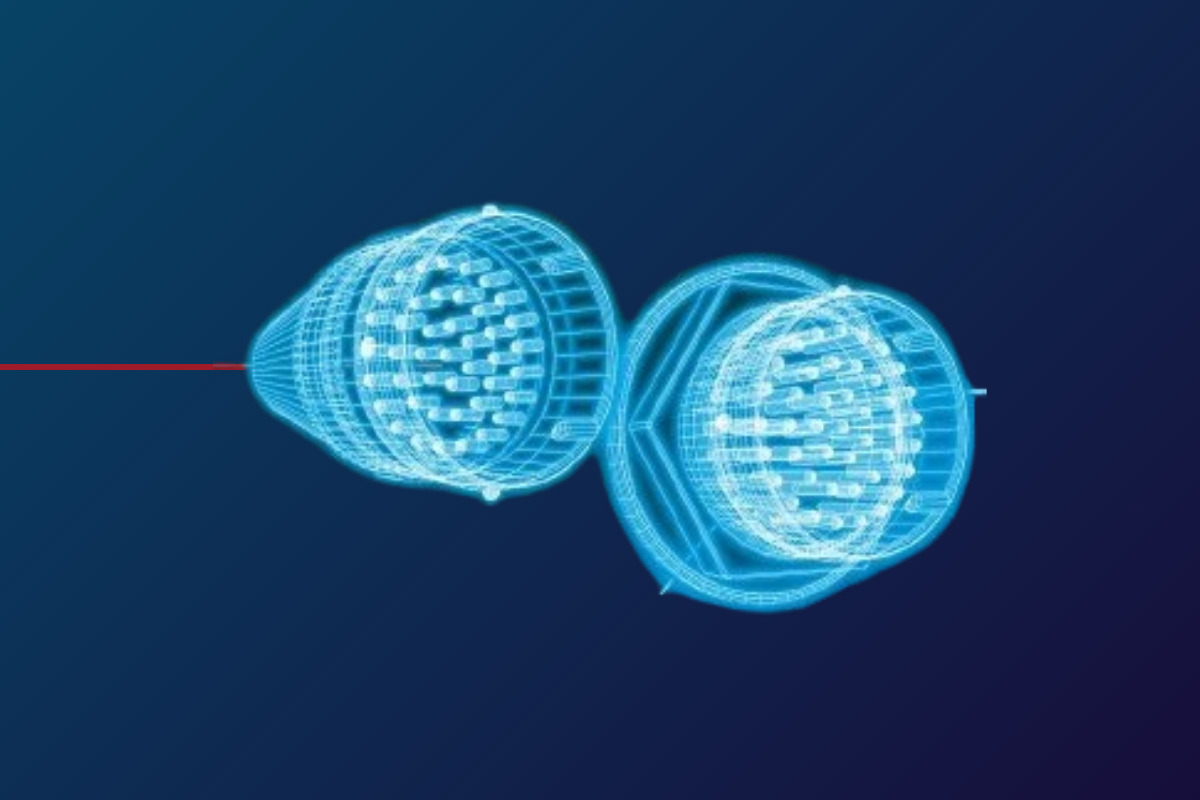

A connector is an electromechanical component that enables an electrical or optical connection between two elements of a system (cables, electronic boards, equipment). It ensures the transmission of signals, data, or power while guaranteeing the reliability and safety of the connection.

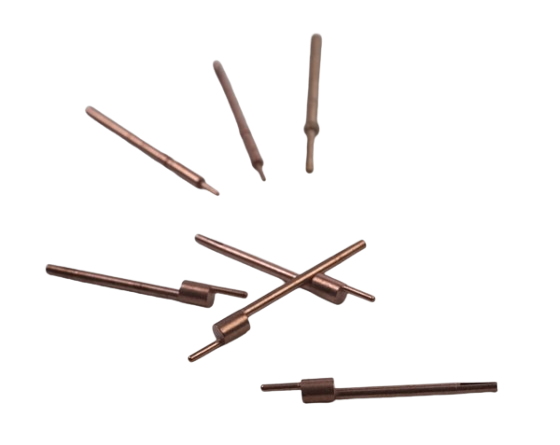

Typically, a connector is composed of:

- Contacts: conductive (metallic) elements that ensure electrical or optical transmission

- Insulators: materials (e.g., plastic) that hold contacts in place and prevent short circuits

- Housing or body: mechanical structure that protects contacts and provides robustness

- Locking system: clips, screws, or mechanisms ensuring mechanical retention

- Wiring interfaces: areas for crimping, soldering, or wire connection

- Environmental protection: seals, waterproofing, EMI/RFI shielding (interference protection)

Challenges in the Connectivity Sector

Technological innovation is critical in the electronics sector. Reliability and performance challenges linked to digitalization and technological integration are more important than ever for industry decision-makers. We have both the capability and the commitment to support our customers through this transformation by offering reliable, responsible, and competitive solutions.

Our commitment: to be more than a supplier — a true industrial partner.

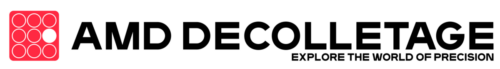

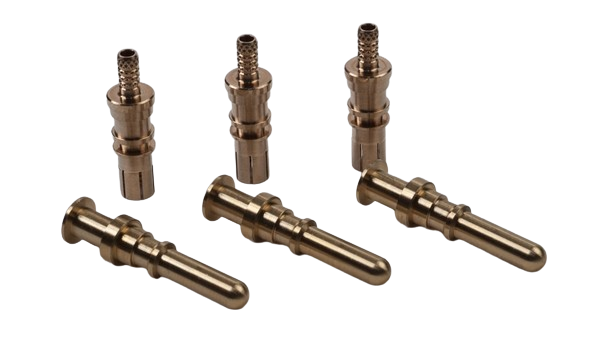

Our production workshops are equipped with single-spindle automatic lathes, rotary transfer machines (8 to 20 stations), and CNC machines, enabling us to manufacture precision-turned parts in small, medium, or large volumes, with diameters ranging from 0.8 mm to 32 mm.

Reliability and Performance in Extreme Environments

- Connectors must withstand harsh conditions: vibration, extreme temperatures, humidity, and mechanical stress.

- The growth of embedded electronic systems in mobility, energy, transportation, aerospace, and defense requires more robust, miniaturized, and certified connectors.

- Compliance with standards (e.g., MIL-SPEC, EN, DO-160…) is a major challenge to ensure equipment safety and longevity.

Digitalization and Technological Integration

- Growth of connected systems (industrial IoT, sensors, advanced avionics): need for connectors capable of handling high data rates and secure transmissions.

- Integration of fiber optics and hybrid solutions (power + data) to meet modern electrical architecture requirements.

- Pressure to reduce weight and optimize compactness without compromising performance.

Securing Supply Chains and Sustainability

- Shortages of electronic components and geopolitical tensions impact connector availability.

- Need for reshoring and supplier diversification to ensure continuity.

- Environmental requirements: recyclable materials, eco-responsible manufacturing processes, RoHS/REACH compliance.

Expertise in High-Performance Connector Turning

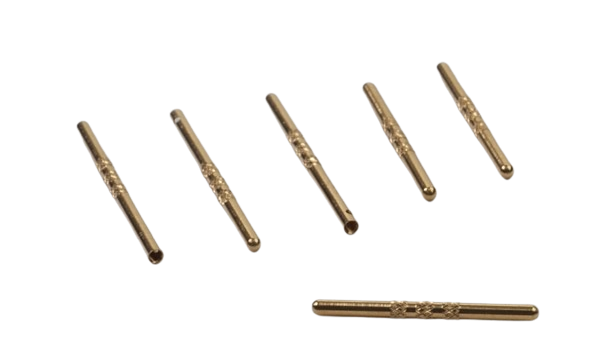

Our expertise covers the machining of contacts, pins, tips, terminals, and miniature components for electrical and electronic connectors:

- High-precision turning: mastery of micrometric tolerances

- Flexible production: small, medium, and large series

- Continuous innovation: digital transformation (Industry 4.0) and annual investments in cutting-edge equipment

- Rigorous quality control: automated visual and dimensional inspections to guarantee zero defects

- Production in France (EUR1), in the heart of the Alps, at the center of Europe, with the capacity to support customers across all five continents

AMD Connectivity Applications by Sector

- Automotive & E-Mobility

Robust connector components for combustion, electric, and hybrid vehicles, meeting stringent reliability and safety requirements (IATF 16949 certification).

Applications include wiring harnesses, ADAS or LIDAR systems, power buses, batteries, and charging connections. - Aerospace & Defense

Miniaturized, high-resistance connectors designed for demanding environments where performance and safety are critical.

Applications include avionics systems, sensors, flight controls, military equipment, and embedded systems. - Industry 4.0 & Data Centers

Connectivity solutions for high-speed data transmission and energy management in digital infrastructures.

Certifications and Quality Commitment

![]() ISO 9001: quality management

ISO 9001: quality management

![]() IATF 16949: automotive requirements, a guarantee of industrial performance

IATF 16949: automotive requirements, a guarantee of industrial performance

![]() ISO 14001: environmental commitment and sustainable development

ISO 14001: environmental commitment and sustainable development

Our certifications demonstrate our rigor and our ability to meet the most stringent industry standards and requirements.

We are available to welcome you should you wish to audit our organization and visit our facilities.

Why Choose AMD Décolletage for Your Connectivity Projects?

![]() Long-standing expertise in connector turning and mechanical component assembly

Long-standing expertise in connector turning and mechanical component assembly

![]() Multisector capability: automotive, aerospace, defense, e-mobility, Industry 4.0

Multisector capability: automotive, aerospace, defense, e-mobility, Industry 4.0

![]() Flexible production tailored to your needs (prototypes → small, medium, and large series)

Flexible production tailored to your needs (prototypes → small, medium, and large series)

![]() Innovation, co-development, quality, and traceability dedicated to performance (D2M: from idea to manufacturing)

Innovation, co-development, quality, and traceability dedicated to performance (D2M: from idea to manufacturing)

![]() Strategic partner for high value-added projects worldwide

Strategic partner for high value-added projects worldwide