From Design to Manufacturing

The Challenges Faced by Our Clients

In an ever-changing and competitive environment, our clients — connector manufacturers, players in industrial mechanics, OEMs, equipment suppliers, and integrators of high-precision mechanical components across all industrial sectors — face major challenges:

- technical uncertainties,

- economic constraints,

- tight deadlines,

- and the need for rapid industrialisation.

These issues lead them to seek partners capable of transforming an idea or prototype into a reliable, competitive, and industrializable solution.

With this objective in mind, AMD Décolletage — a specialist in high-precision turning since 1978 and located in the heart of the Alps — offers structured support through 5 key steps, from feasibility analysis to mass production, providing concrete answers to our customers’ challenges:

![]() Technical feasibility: miniaturisation, tight tolerances, complex geometries

Technical feasibility: miniaturisation, tight tolerances, complex geometries

![]() Wide range of materials: steel, stainless steel, aluminium, brass, copper…

Wide range of materials: steel, stainless steel, aluminium, brass, copper…

![]() Cost optimisation: material selection, manufacturing processes, automation

Cost optimisation: material selection, manufacturing processes, automation

![]() On-time delivery: rapid ramp-up, flexible production resources

On-time delivery: rapid ramp-up, flexible production resources

![]() Compliance with your requirements and regulatory constraints: ISO 9001, IATF 16949, and ISO 14001

Compliance with your requirements and regulatory constraints: ISO 9001, IATF 16949, and ISO 14001

![]() Co-design: close collaboration to adapt the part to industrial constraints

Co-design: close collaboration to adapt the part to industrial constraints

Each project is managed according to a certified process (ISO 9001, IATF 16949, ISO 14001). We act as a strategic partner to secure and accelerate your industrial projects.

A technical and sales team ready to support you: contact us!

“D2M: From Design to Manufacturing — a simple, fast and highly appreciated service, delivering maximum results!”

- Contact us directly: sales@amd-decolletage.fr or HERE

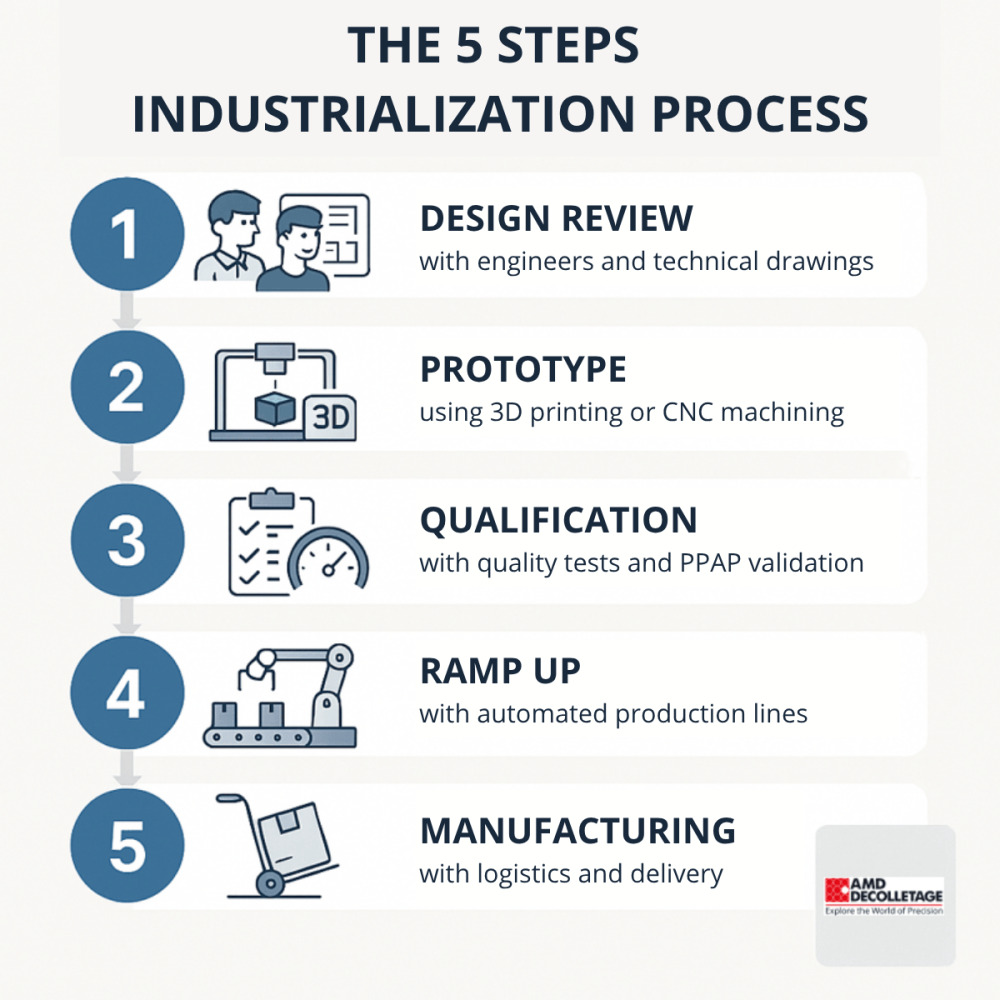

5-Step Co-Engineering Service

1. Design Review

- Submission of project description, drawings and 3D files

- Online meeting to review the request together and plan the next steps

- Internal feasibility analysis and budgeting

- Detailed budgetary offer

2. Prototype

- Prototype manufacturing for functional and mechanical testing

- “Test & Learn” approach to refine the design based on your feedback

- Rapid iterations to validate technical decisions

3. Qualification & PPAP

- Execution of qualification tests for the developed part

- Optional PPAP (Production Part Approval Process) documentation

- Validation of customer quality requirements before mass production

4. Ramp-Up

- Cost/time analysis to meet your production targets

- Adaptation of industrial resources for production scale-up

- Investment studies to automate high-volume production

5. Mass Production

- Signing of an annual or multi-year production contract

- Launch of manufacturing orders according to your needs

- Tailored logistics services, with worldwide delivery

Example Project in Electric Mobility: From Concept to Industrialisation

E-Mobility Focus: High-Precision, Tailor-Made Solutions

Since 2010, electric vehicle (EV) manufacturers and OEMs have been developing electrification projects. AMD Décolletage supports their design teams to meet technical requirements and industrialise new terminals and connectors.

Every day, when you charge your electric vehicle, chances are you are using an AMD contact — particularly through Type 2, NACS, CCS 1 & 2, or GBT standards.