Mechanical parts for high technology industries

In parallel with Connectors and Mobility markets, we are serving high end industries involving precision turning needs. We support our client from design to manufacturing. They found precision turned parts for thier application and usage such as:

- Sensors

- Home appliances

- Textile machines

- Robotic

- IoT and embedded electronic

- Energy,

- Railway & Truck

- Defence & Aerospace

- High technology industries

We would be pleased to share with you our expertise and study any project that you may have.

Objective : Overcoming industry challenges

In today’s fast-paced and competitive industrial landscape, our clients—connector manufacturers, industrial mechanics specialists, OEMs, equipment suppliers, and integrators of precision mechanical components—face a range of critical challenges:

- Technical uncertainties

- Economic constraints

- Tight deadlines

- The need for rapid industrialisation

These pressures demand partners who can transform an idea or prototype into a reliable, competitive, and industrialisable solution.

From Design to Manufacturing #D2M

#D2M is a co-engineering service for high precision mechanical parts industrialisation

French version / Version Francaise

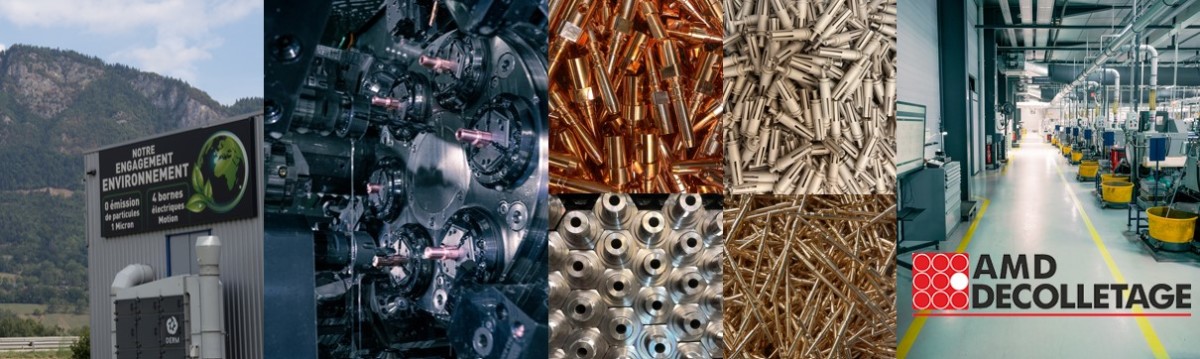

AMD Décolletage: Precision Turning Since 1978

Based in the heart of the French Alps, AMD Décolletagehas been a trusted expert in high-precision turning since 1978.

We offer a structured, five-step support process that guides your project from feasibility analysis to full-scale production, delivering concrete solutions to your industrial challenges:

- Technical feasibility: miniaturisation, tight tolerances, complex geometries

- Wide material range: Steel, Stainless Steel, Aluminium, Brass, Copper…

- Cost optimisation: material selection, manufacturing processes, automation

- On-time delivery: rapid ramp-up, flexible production resources

- Regulatory compliance: ISO, IATF, EN standards

- Co-design: close collaboration to adapt parts to industrial constraints

All projects are managed under certified processes (ISO 9001, IATF 16949, ISO 14001), ensuring quality, traceability, and performance. We position ourselves as a strategic partner to secure and accelerate your industrial projects.

Our 5-Step Co-Engineering process

1. Design Review

- Submit your project description, drawings, and 3D files

- Video meeting to review the request and plan the next steps

- Internal feasibility analysis and budgeting

- Detailed budget proposal

2. Prototyping

- Production of prototypes for functional and mechanical testing

- “Test & learn” approach to refine the design based on your feedback

- Rapid iterations to validate technical decisions

3. Qualification & PPAP

- Execution of qualification tests on the designed part

- Optional PPAP (Production Part Approval Process) documentation

- Validation of customer quality requirements before series launch

4. Ramp-Up

- Cost and lead time analysis to meet your production targets

- Adaptation of industrial resources to support increased volumes

- Investment studies for automation in large-scale production

5. Mass Production

- Signing of annual or multi-year production contracts

- Launch of manufacturing orders based on your needs

- Tailored logistics services with global delivery

Initialy published on : Linked in July 2025

You are welcome to consult us!