From design to manufacturing

Our clients are leading manufacturers and OEMs from the Connector and interconnection, e-Mobility, Sensors, Embedded electronic, Automotive and industrial sectors.

Custom made parts according to your drawings and specifications, AMD provide capability to support from design, prototype and qualification (PPAP) to ramp-up and series manufacturing.

We look forward about the opportunity of collaborating with you in the future

>>> You have a new project : contact us here

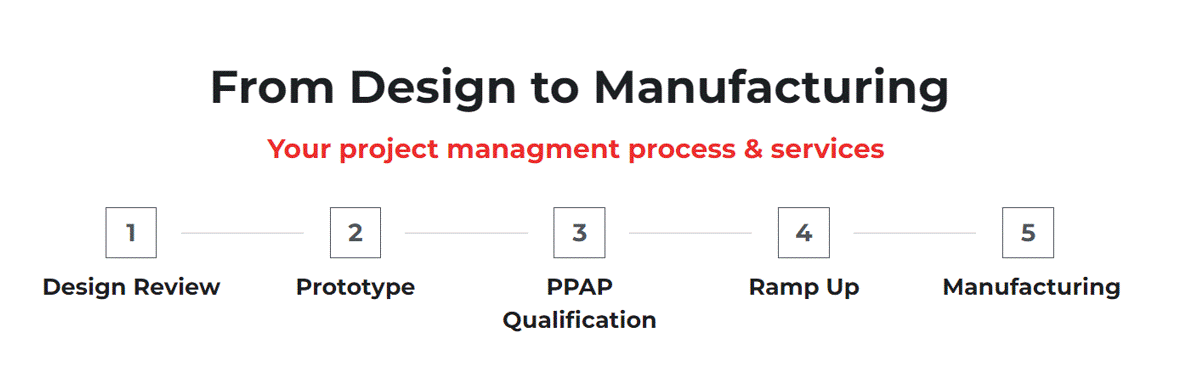

A 5 steps project management (PM) service

Our clients ask us to support their industrialisation and production from design up to series production. An a daily basis, they have custom requirements to meet and we support thier decision by sharing our know how and expérience throught a 5 steps project managment process.

To simplify client project managment from design to serial manufacturing, we offer a 5 steps work flow service:

- Design Review:

- Send project description, drawings and 3d files

- Visio call to reveiw together your demand and phase our agenda

- Internal feasability and budget analysis

- Budgetary offer

- Prototype

- To run your test , you place a prototype order

- “Lesson / learn” approach (loop) to finalize the design as per your requirements

- PPAP & Qualification

- You run your test to qualify the designed part

- We offer a PPAP service (option on demand)

- Ramp Up production

- Cost/Lead Time/Cost analysis review to meet your objective

- Manufacturing means are adapted to your ramp up curve

- We study industrial investment to automatised large production volume

- Serie Manufacturing

- Annual or multi-annual production service contract agreement signed

- Production order is launch in regards with your annual needs

- Logistic services is adapted to your request : wordwilde delivery service

About AMD Decolletage

AMD Decolletage is specialized in manufacturing precision CNC machined turned-milled components with a high quality standard.

Based in the French Alpes, since 1978 , we provide 100% in house production (made in France-Europe) all around the globe.

Expert in high precision turning from brass, lead free material, copper, stainless steel, and aluminium alloys.

Finally, we offer added value services to full file your client technical requirement and economic target.

Our quality management system complies with the requirements of following standards: ISO 9001 / IATF 16949 / ISO 14001

We look forward about the opportunity of collaborating with you in the future

>>> Contact page

>>> Here our new company presentation leaflet