AMD Decolletage @ Elmia Subcontractor Fair Elmia Subcontractor, 14-16 November 2023

Elmia Subcontractor, 14-16 November 2023

Join us booth C30 : 30

“Elmia Subcontractor is the heart of the industry, providing it with oxygen, energy and momentum for three effective days. It brings together thousands of like-minded people to share knowledge, create innovations and do business right on the hall floor. On site. With joy. And with tomorrow’s solutions in focus.”

Made in the Alps : this region called “Technic Vallée” is considered as the heartland of the precision screw-machining world. Originally, AMD Decolletage has started the manufacturing of precision screw machined parts for the connectors industry.

Beeing resolutely committed to the “Sustainable, Profitable and Harmonious growth”, our ambition is to become the partner of reference.In order to achieve our ambitions, the actions which have been already deployed in the field of Quality, Security and Environment should be continuously improved and strengthened.

Our quality management system complies with the requirements of following standards: ISO 9001 / IATF 16949 / ISO 14001

In 2000, AMD join the Groupe SAVOY Mechanical Branch. In Groupe SAVOY, we are convinced that the well-being of our 1,000 employees is the foremost vector of wealth for our group. This is why we use the term “Human wealth ” to speak about the women and men who work for the Savoy International group. Our industrial performance is deployed around our LEAN SAVOY INTERNATIONAL 4.0.

For several decades the Group has been consistently acquiring or developing all the technologies used to design and manufacture mechatronic systems. The Group has an expert command of a large number of technologies from bar turning, to fine cutting, including plastic injection, design and manufacture of printed circuit boards, very high-speed assembly, 3D laser metal and plastic printing (also named additive manufacturing). Our R&D services offer design, laboratory qualification and production capabilities in an environment geared towards process and product innovation.

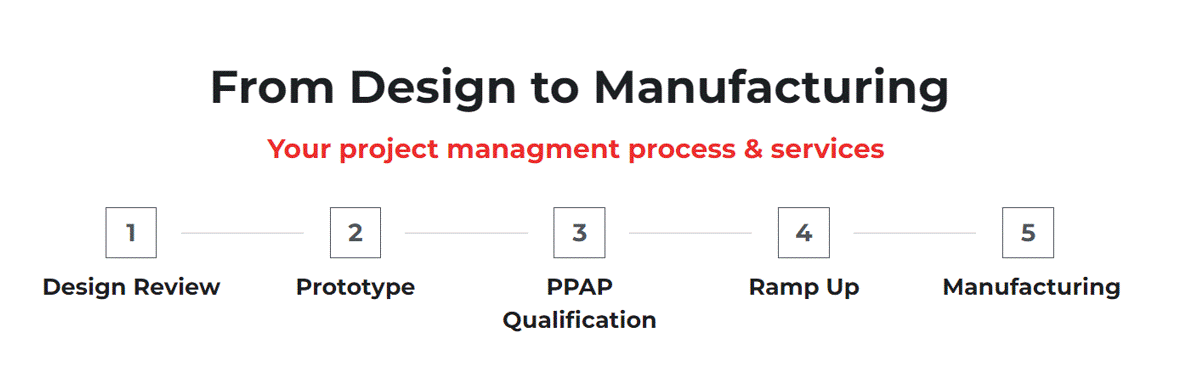

From Design to Manufacturing : 5 steps project management (PM) service

Our clients ask us to support their industrialisation and production from design up to series production. on a daily basis, they have custom requirements to meet and we support thier decision by sharing our know how and expérience throught a 5 steps project managment process.

To simplify client project managment from design to manufacturing, we offer a 5 steps work flow service:

- Design Review:

- Send project description, drawings and 3d files

- Visio call to reveiw together your demand and phase our agenda

- Internal feasability and budget analysis

- Budgetary offer

- Prototype

- To run your test , you place a prototype order

- “Lesson / learn” approach (loop) to finalize the design as per your requirements

- PPAP & Qualification

- You run your test to qualify the designed part

- We offer a PPAP service (option on demand)

- Ramp Up production

- Cost/Lead Time/Cost analysis review to meet your objective

- Manufacturing means are adapted to your ramp up curve

- We study industrial investment to automatised large production volume

- Serie Manufacturing

- Annual or multi-annual production service contract agreement signed

- Production order is launch in regards with your annual needs

- Logistic services is adapted to your request : wordwilde delivery service